The automatic control system in Penguin Group's automated sesame oil production line plays a crucial role in ensuring production continuity and stability. For example, in the raw material cleaning process, the system can precisely control the water flow and cleaning time. According to industry data, with the advanced automatic control system, the cleaning efficiency can be increased by up to 30% compared to traditional methods. This not only saves time but also ensures that the raw materials are thoroughly cleaned, laying a good foundation for subsequent production processes.

In the oil extraction process, the automatic control system can adjust the temperature and pressure in real - time according to the characteristics of the raw materials. This helps to achieve a stable oil extraction rate. On average, the oil extraction rate of this production line can reach over 45%, which is significantly higher than the industry average of about 40%.

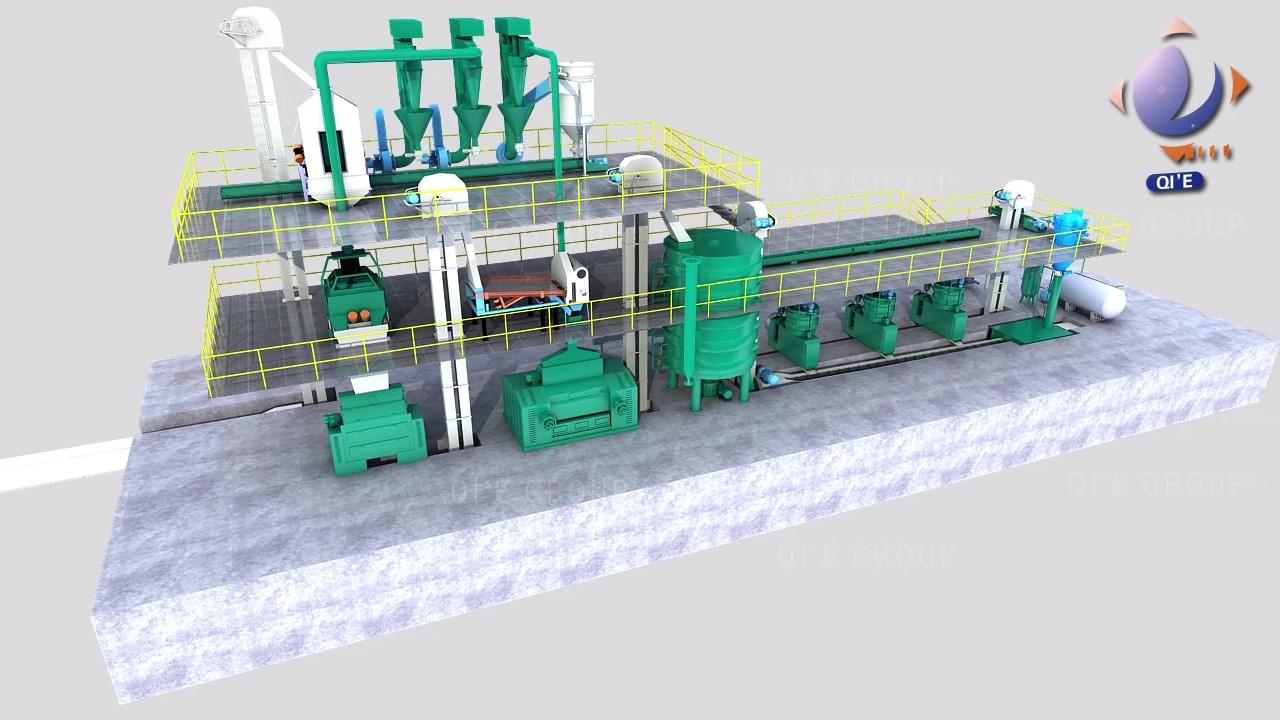

The entire production process from raw material cleaning, drying, oil extraction, filtration to automatic filling is a well - coordinated process. The fully enclosed production system is a highlight in terms of product safety. In the raw material cleaning stage, the fully enclosed design prevents external contaminants from entering, ensuring the purity of the raw materials. When it comes to the drying process, the system can accurately control the temperature and humidity, reducing the risk of mold growth. This is particularly important as moldy raw materials can produce harmful substances that affect the quality of the final product.

During the oil extraction process, the fully enclosed system not only maintains a clean production environment but also reduces the loss of volatile substances, thus preserving the high - quality flavor and nutritional value of the sesame oil. In the filtration stage, the system can remove impurities more effectively, and the filtration precision can reach up to 0.1 microns, ensuring that the final product has high clarity and purity.

Penguin Group's automated sesame oil production line is designed with advanced environmental and energy - saving concepts. In terms of energy - saving, the production line uses a heat - recovery system. For example, the heat generated during the oil extraction process can be recycled and used for the drying of raw materials. This can save up to 25% of energy consumption. The use of energy - efficient motors and intelligent control systems also helps to reduce power consumption. On average, the power consumption per unit of production is reduced by about 20% compared to traditional production lines.

From an environmental perspective, the fully enclosed production system reduces the emission of waste gas and dust. The waste generated during the production process can be effectively treated and recycled, minimizing the impact on the environment. For instance, the solid waste after oil extraction can be used as organic fertilizer, realizing the comprehensive utilization of resources.

During the development and application of this production line, Penguin Group has encountered various technical difficulties. One of the main challenges was to achieve a balance between energy - saving and high - quality production. Through continuous research and development and experimentation, the company found that by optimizing the automatic control system and the design of the heat - recovery system, it could effectively solve this problem.

Another difficulty was to ensure the long - term stability of the fully enclosed production system. To address this, the company adopted high - quality sealing materials and regular maintenance plans. These measures have effectively improved the reliability of the production system. Based on practical experience, Penguin Group can provide valuable reference for other enterprises in the industry to solve similar problems.

Penguin Group's automated sesame oil production line, with its advanced automatic control system, fully enclosed production system, and environmental and energy - saving design, is a leading solution in the modern grain and oil machinery industry. It not only improves production efficiency, ensures product quality but also meets the market demand for environmental protection and energy - saving. If you are looking for a reliable and innovative solution for your sesame oil production, don't miss Penguin Group's automated sesame oil production line. Click here to learn more about Penguin Group's cutting - edge sesame oil production solutions!