Edible oil production is a complex process that involves multiple stages, from raw material processing to final packaging. In the modern manufacturing environment, the Programmable Logic Controller (PLC) system plays a crucial role in automating and optimizing these processes. However, many edible oil factories still struggle with frequent shutdowns caused by PLC malfunctions.

Let's take a real - world example. A medium - sized edible oil manufacturer was experiencing an average of 5 non - planned shutdowns per month due to PLC issues, leading to a 15% reduction in overall production efficiency and a significant increase in maintenance costs.

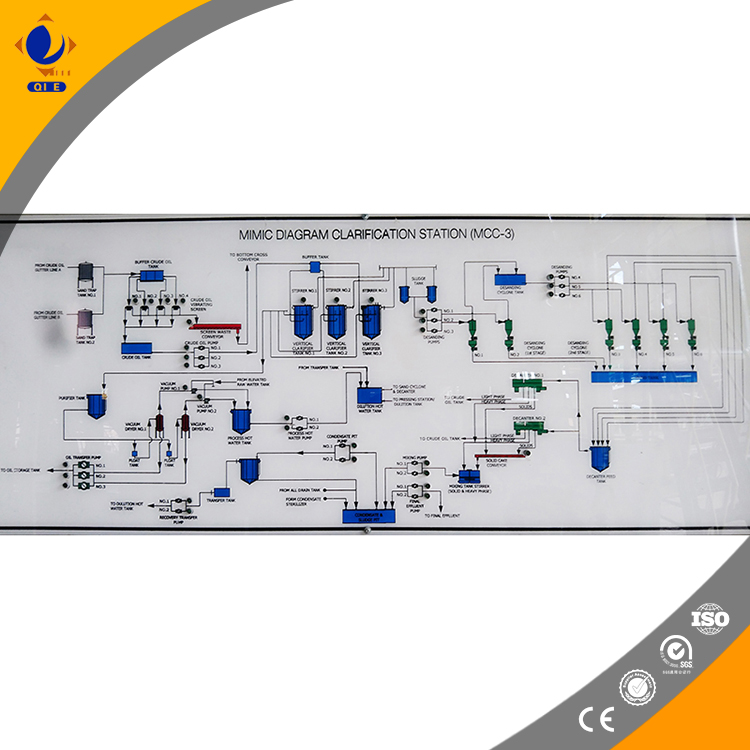

The PLC system has core control functions in every step of the edible oil production process, including raw material handling, cold pressing, solvent extraction, refining, and filling. For example, in the raw material handling stage, the PLC can precisely control the amount of raw materials fed into the system, ensuring a stable production rate. In the refining process, it can automatically adjust key parameters such as temperature and pressure to meet the quality standards.

The automatic adjustment mechanism of key parameters like temperature and pressure is based on pre - set algorithms. These algorithms can monitor the real - time data of the production line and make adjustments accordingly. For instance, if the temperature in the refining tank is too high, the PLC will automatically adjust the cooling system to bring the temperature back to the normal range.

Remote monitoring and early warning systems are essential for reducing the risk of shutdowns. By continuously monitoring the PLC system from a remote location, the technical team can detect potential problems in advance. For example, through data analysis, if the system detects an abnormal increase in the current of a certain motor, it can send an early warning signal to the technicians, allowing them to take preventive measures before a serious breakdown occurs.

Based on an anonymous customer case, typical PLC faults in edible oil production often include communication failures, sensor malfunctions, and program errors. Through proper diagnosis and troubleshooting, the technicians can quickly identify and resolve these issues. For example, in one case, a communication failure was detected by analyzing the network traffic data of the PLC system. After replacing a faulty communication module, the system was restored to normal operation.

Compared with traditional manual control, PLC automatic adjustment has significant advantages in terms of equipment efficiency and energy consumption management. Manual control often leads to human errors and inconsistent operation, resulting in lower production efficiency and higher energy consumption. In contrast, PLC automatic adjustment can ensure stable and accurate operation, reducing energy consumption by up to 20% and increasing equipment efficiency by 15% according to some industry statistics.

To maintain the normal operation of the PLC system, a regular inspection is necessary. We provide a detailed inspection checklist, including checking the power supply, communication lines, and sensor status. In addition, we also offer a remote setting guide, which allows the technicians to configure the system parameters remotely, saving time and effort.

Penguin Group's self - developed PLC equipment is designed with advanced technology and high - quality components, ensuring high reliability and stability. Our professional after - sales service team provides 24/7 support to help you solve any problems you may encounter during the operation of the system.

Are you tired of frequent shutdowns in your edible oil factory? Upgrade your production line with Penguin Group's advanced PLC control system and enjoy a more stable and efficient production process. Click here to learn more!