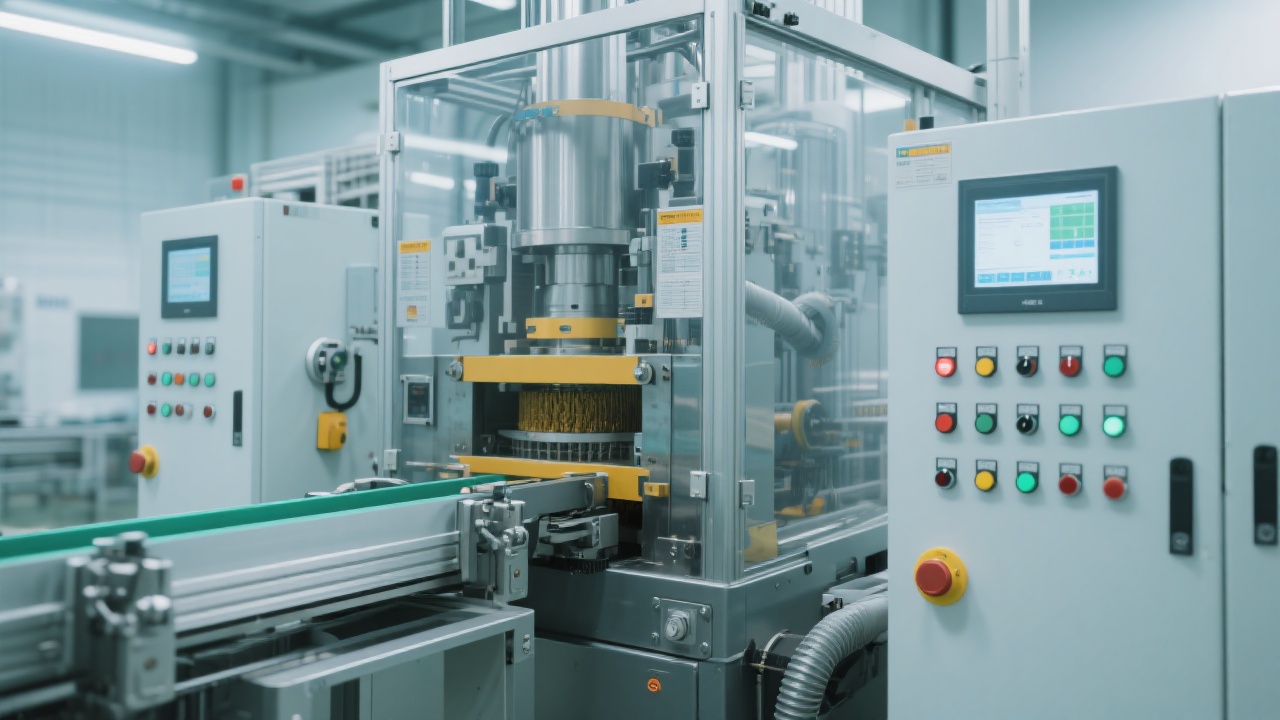

Are you tired of your fully automatic rapeseed oil production line frequently shutting down due to PLC abnormalities? In the modern industrial landscape, the Programmable Logic Controller (PLC) has become the nerve center of the edible oil production line, governing every step from raw material pre - treatment to final product filling. This article will be your comprehensive guide to troubleshooting common PLC faults and implementing preventive maintenance strategies.

The PLC in an edible oil production line manages a series of complex processes. In the raw material pre - treatment stage, it precisely controls the temperature and moisture of the raw materials, ensuring optimal conditions for subsequent processing. During the pressing phase, it synchronizes the operation of multiple motors to maintain a consistent pressing force. In the refining and filling processes, it monitors and adjusts parameters such as oil quality and filling volume.

Imagine a well - choreographed dance where every move is crucial. That's what the PLC does in your edible oil production line. Without proper control, the entire production process can fall into chaos, leading to reduced product quality and increased production costs.

Sensors are the eyes and ears of the PLC system. However, they can sometimes give false alarms due to dust, moisture, or electrical interference. For example, a temperature sensor in the refining tank may report an incorrect temperature, causing the PLC to make wrong adjustments.

To troubleshoot this, you can start by cleaning the sensors regularly. Check the wiring connections for any loose or damaged parts. In a real - world case, a company reduced sensor false alarms by 80% after implementing a monthly sensor cleaning and inspection program.

In the pressing and filling processes, multiple motors need to work in sync. If there is a synchronization deviation, it can lead to uneven pressing or inaccurate filling. This may be caused by worn - out motor components or incorrect PLC programming.

To address this issue, you can perform regular motor maintenance, including lubrication and component replacement. Also, review and optimize the PLC programming to ensure accurate motor control. A factory managed to reduce motor synchronization errors by 70% through these measures.

A daily inspection is the first line of defense against PLC failures. Here is a simple checklist:

Remote monitoring allows you to keep an eye on your PLC system 24/7. You can set up alerts for abnormal conditions, such as over - temperature or sensor malfunctions. This way, you can take immediate action before a small problem turns into a major breakdown. By implementing remote monitoring, a company reduced unplanned downtime by 60%.

Let's look at some data to understand the benefits of PLC - controlled production. In a traditional edible oil production line with manual control, the energy consumption was relatively high. After switching to a PLC - controlled system, the energy consumption decreased by 30%. Also, the unplanned downtime was reduced from an average of 10 days per year to just 2 days.

To help you better manage your PLC system, we provide downloadable tools such as a fault troubleshooting table and a daily inspection log. These tools will assist you in quickly identifying and resolving problems, as well as maintaining a systematic maintenance record.

Master these skills, and you can turn your PLC into the guardian angel of your production. Don't miss out on the opportunity to optimize your edible oil production line. Click here to learn more about our advanced PLC solutions for edible oil production lines.