In the competitive landscape of the grain and oil processing industry, achieving high - efficiency and high - quality sesame oil production is a top priority for enterprises. Penguin Group's automated sesame oil production line offers a comprehensive solution, integrating cutting - edge technologies to streamline the entire production process.

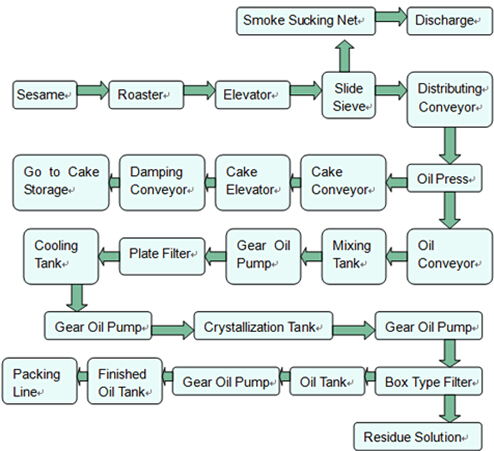

The automated sesame oil production line of Penguin Group covers a full - cycle process from raw material cleaning, drying, oil extraction, filtration to automatic filling. The advanced automatic control system plays a crucial role in ensuring the continuity and stability of production. For example, in the oil extraction process, the automatic control system can precisely adjust the temperature and pressure, with a temperature control accuracy of ±1℃ and a pressure control accuracy of ±0.5 MPa. This high - precision control reduces human error and improves the consistency of product quality.

A fully enclosed production system is one of the highlights of this production line. It effectively isolates the production environment from the external world, preventing contamination from dust, microorganisms, and other pollutants. According to industry standards, the fully enclosed system can reduce the microbial contamination rate by more than 80%, significantly improving product safety. Moreover, it helps maintain a stable internal environment, which is beneficial for maintaining the quality stability of sesame oil. For instance, the oxidation rate of sesame oil in a fully enclosed system is reduced by about 30% compared to an open - type production system.

In today's era of increasing emphasis on sustainable development, the environmental - friendly and energy - saving design of the sesame oil production line is of great significance. Penguin Group's production line adopts a series of energy - saving technologies, such as waste heat recovery. The waste heat generated during the drying and oil extraction processes can be recycled to pre - heat the raw materials or for other auxiliary processes, reducing energy consumption by approximately 25%. At the same time, the use of low - power and high - efficiency equipment further reduces the overall energy consumption of the production line.

The application of this automated sesame oil production line has brought tangible benefits to many grain and oil processing enterprises. It has improved production efficiency, with an average increase in production capacity of 30% compared to traditional production lines. The high - quality sesame oil produced also meets international standards, enhancing the market competitiveness of enterprises. For example, some enterprises using this production line have seen a 20% increase in their market share in the high - end sesame oil market.

In conclusion, Penguin Group's automated sesame oil production line combines advanced technologies, a fully enclosed production system, and environmental - friendly and energy - saving design concepts. It provides a reliable solution for grain and oil processing enterprises to achieve high - purity, high - nutritional - value sesame oil production. If you are looking to upgrade your sesame oil production line and improve your market competitiveness, click here to learn more about our comprehensive product solutions.