In modern sesame oil production, automation plays a pivotal role in enhancing process stability and efficiency. The central backbone of this automation is the well-configured control system, primarily composed of Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), sensors, and actuators. These core modules interconnect to realize precise process control, real-time monitoring, and timely production adjustments.

The PLC acts as the system’s brain, executing logic commands based on input from sensors that capture temperature, flow rate, and pressure—all critical parameters for sesame oil extraction and refinement. The HMI offers operators an intuitive platform to observe process variables and modify setpoints instantly without halting production.

Proficient integration of hardware and software is essential for peak operational performance. Typically, the control system hardware includes:

| Component | Role | Key Features |

|---|---|---|

| PLC Unit | Centralized logic processing and control | High-speed CPUs, modular I/O, robust industrial-grade design |

| Touchscreen HMI | User interface for monitoring and parameter adjustment | Graphical display, alarm notifications, easy navigation |

| Sensors (Temperature, Flow, Pressure) | Real-time process data acquisition | High accuracy ±0.5%, fast response times |

| Actuators (Valves, Motors) | Physical execution of control commands | Precision operation, compatibility with PLC outputs |

On the software side, seamless communication protocols such as Modbus RTU or Ethernet/IP facilitate reliable data exchange. Parameter configuration tools embedded within PLC programming environments allow fine-tuning of control loops and scheduling to adapt for production shifts.

Optimizing PLC parameters is critical in synchronizing different stages of sesame oil extraction—from seed roasting to pressing and clarification. Proper calibration increases throughput by up to 20% and reduces material waste by roughly 15%, translating into tangible cost savings.

Key tuning parameters include:

Employing PID (Proportional-Integral-Derivative) control algorithms integrated in PLCs helps in accurate real-time corrections, ensuring the production stays within ideal operational zones.

Consistent system health checks and rapid fault diagnosis safeguard continuous production. Recommended practices include:

Troubleshooting steps should follow a systematic approach starting with software diagnostics—analyzing PLC error codes and reviewing event logs—followed by physical inspection of wiring and hardware components.

.jpg)

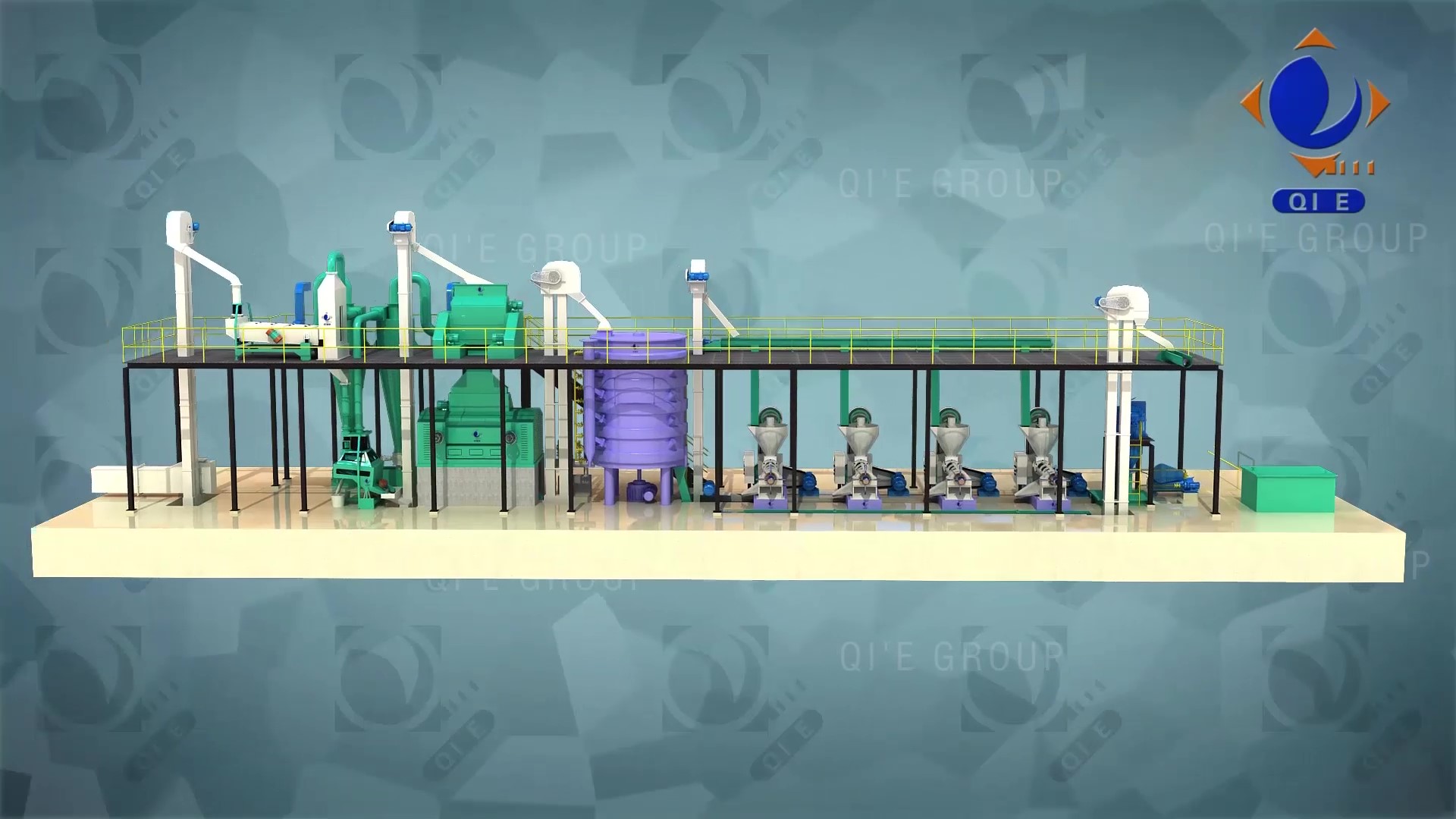

Different business scales necessitate tailored automation strategies. Small-to-medium enterprises may benefit from modular control systems allowing phased upgrades, while large producers often require fully integrated solutions encompassing:

Selecting the right combination hinges on analyzing current workflows, budget constraints, and future scalability. Engaging with specialized automation consultants will ensure the design aligns perfectly with operational goals.

For professionals striving to elevate sesame oil production lines through profound automation insights and pragmatic system tuning, Download Our Complete PLC Parameter Optimization Manual today and connect with our expert community for ongoing technical support and knowledge exchange.