In the highly competitive landscape of the edible oil industry, the demand for high - quality sesame oil has been on the rise. To meet this demand, automation has become a key factor in sesame oil production. This article delves into the core technologies of automated sesame oil production lines, highlighting how they enhance production continuity and stability.

From raw material processing to finished product filling, every step of an automated sesame oil production line is designed with a focus on stability and continuity. The raw material processing stage, which includes cleaning and drying, is crucial. An advanced cleaning system can remove impurities effectively, ensuring the quality of the final product. For example, a well - designed cleaning machine can reduce the impurity rate to less than 1%, which is a significant improvement compared to traditional methods. After cleaning, the drying process is carefully controlled to achieve the optimal moisture content for subsequent oil extraction. Usually, the moisture content of the dried sesame seeds should be around 6 - 8% for the best oil - yielding results.

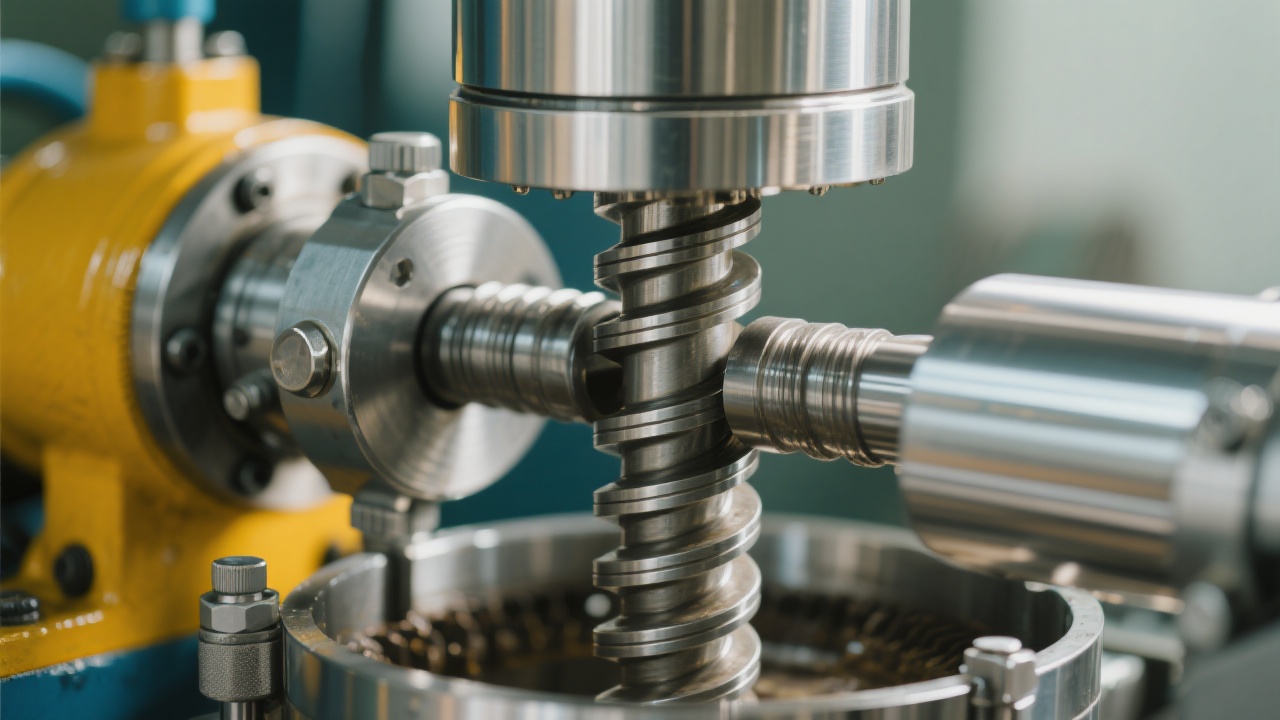

Automatic control systems play a pivotal role in reducing human intervention and improving operational consistency. In an automated sesame oil production line, these systems can precisely control parameters such as temperature, pressure, and flow rate. For instance, during the oil extraction process, the automatic control system can maintain the temperature at 120 - 130°C, which is the ideal range for maximizing oil yield and quality. By minimizing human error, the system ensures that each batch of sesame oil has consistent quality. According to industry data, the use of automatic control systems can increase the consistency of product quality by up to 30%.

A fully enclosed production system is a game - changer in sesame oil production. It effectively prevents contamination, ensuring food safety and quality consistency. This system creates a sealed environment from the raw material input to the finished product output, minimizing the risk of external pollutants such as dust, bacteria, and insects. For example, in a fully enclosed system, the probability of microbial contamination can be reduced by more than 80%. Moreover, it helps to maintain the aroma and flavor of sesame oil, as the volatile components are less likely to escape during the production process.

Environment - friendly and energy - saving designs are another highlight of modern automated sesame oil production lines. These designs can significantly reduce energy consumption while increasing production capacity. For example, some advanced production lines use heat - recovery systems, which can recycle up to 50% of the waste heat generated during the production process. This not only reduces energy costs but also lowers the environmental impact. In addition, energy - efficient motors and pumps are used to further cut down on power consumption. As a result, the overall energy consumption of the production line can be reduced by 20 - 30%, while the production capacity can be increased by 15 - 20%.

The sesame oil production industry faces several pain points, such as high production costs, inconsistent product quality, and environmental concerns. To address these issues, the use of automated production lines with advanced technologies is a viable solution. By adopting automatic control systems and fully enclosed production systems, enterprises can improve product quality and reduce production costs. The environment - friendly and energy - saving designs also help to meet the increasing environmental requirements.

In conclusion, the automated sesame oil production line is a revolutionary solution for the sesame oil industry. It combines advanced technologies to achieve continuous and stable production, while also being environmentally friendly and energy - efficient. If you are a professional in the industry or a decision - maker, don't miss out on the opportunity to upgrade your production capabilities. Contact our technical team now to get a customized automation upgrade plan!

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)