The complexity and capital intensity of establishing a rapeseed oil production line often present formidable challenges for enterprises entering the edible oil industry. Module-based production systems, by decomposing the entire process into flexible, scalable units, offer a strategic solution to these obstacles. This article explores the benefits of modular design in rapeseed oil production, focusing on rapid commissioning, investment risk mitigation, and alignment with international food safety standards.

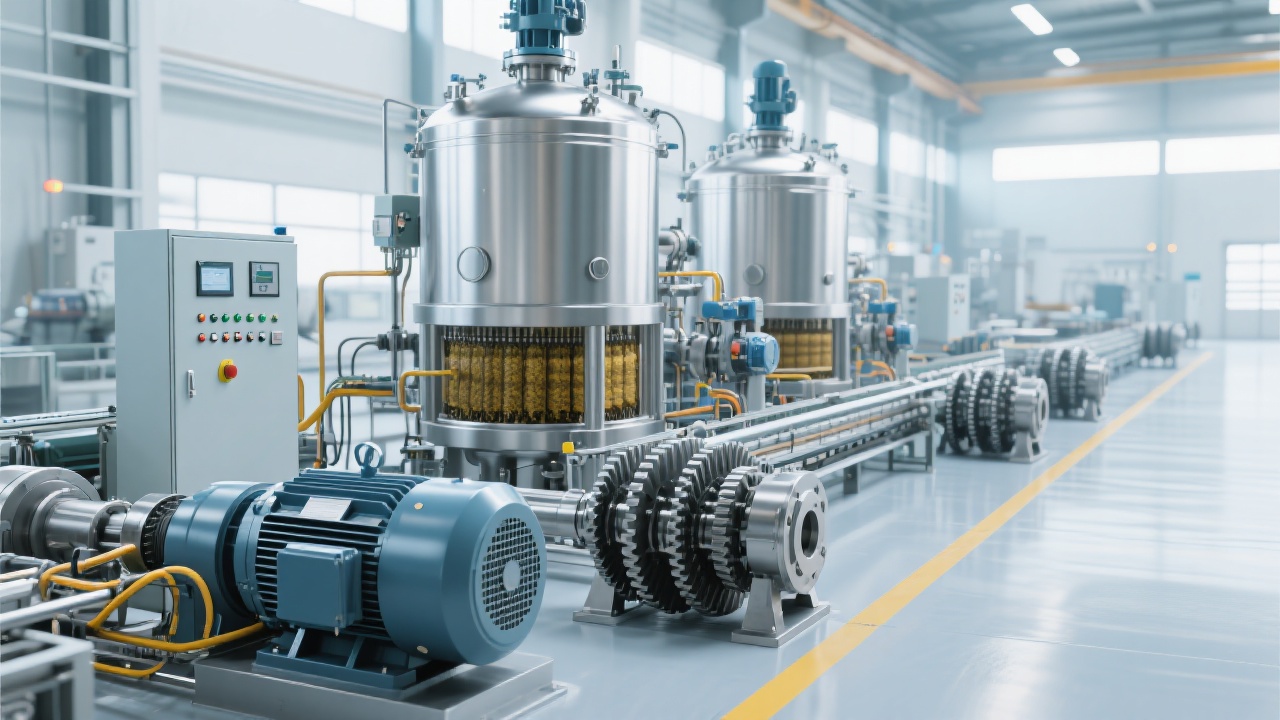

Modular design breaks down the traditional rapeseed oil production workflow into distinct functional units—such as raw material preprocessing, pressing, degumming, bleaching, and deodorizing. Each module operates independently but integrates seamlessly, allowing businesses to tailor capacity and configuration based on specific production goals. According to industry data, modular setups can reduce project timelines by 25-40%, enabling companies to react swiftly to market demands and optimize capital allocation.

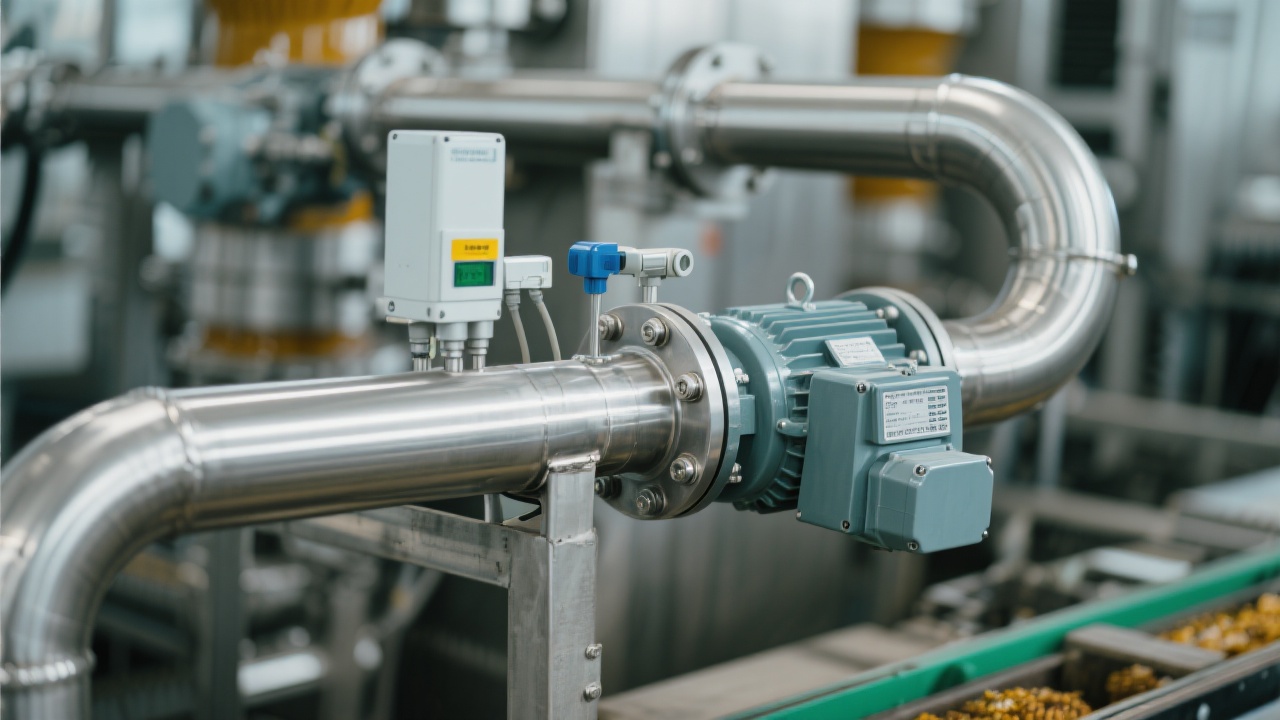

Raw material variability poses a significant risk to production efficiency and product quality. Leveraging modular design, manufacturers can fine-tune processing parameters—such as temperature, pressure, and retention time—in individual modules to accommodate regional rapeseed qualities. For instance, adjusting the degumming module for higher phospholipid content typical in northern hemisphere crops improves yield by up to 8%, while maintaining compliance with Codex Alimentarius and ISO 22000 food safety standards.

Traditional edible oil production lines often entail significant upfront capital—averaging $2 million to $5 million for mid-sized plants—with extended lead times exceeding 12 months. Modular lines allow phased investments aligned with demand growth, reducing initial capital expenditure by 30–50%. Additionally, modularity mitigates technological obsolescence risks, as individual units can be upgraded or replaced without full system downtime.

Successful adoption of modular production lines depends not only on hardware design but also on comprehensive operational support. Detailed standardized operation manuals, customized technical training programs, and a proactive after-sales service network enable seamless startup and maximize uptime. For example, a leading rapeseed oil manufacturer reported a 20% increase in operational stability and a 15% reduction in maintenance costs after implementing such support tailored for their module-based plant.

Modular production lines inherently facilitate compliance thanks to standardized unit operations that simplify quality control and traceability. Modules can be designed to meet stringent international certifications such as HACCP, ISO 22000, and FDA guidelines. This feature is pivotal for export-oriented enterprises aiming to access lucrative global markets, where adherence to food safety protocols is non-negotiable.

| Module | Primary Function | Customization Scope |

|---|---|---|

| Raw Material Preprocessing | Cleaning, drying, and conditioning | Adjustable cleaning mechanisms for crop-specific impurities |

| Pressing | Oil extraction from seeds | Modifiable pressure and temperature settings |

| Degumming | Removal of phospholipids and gums | Optimized for regional seed profiles |

| Bleaching & Deodorizing | Purification and odor elimination | Variable duration and adsorbent types |

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)