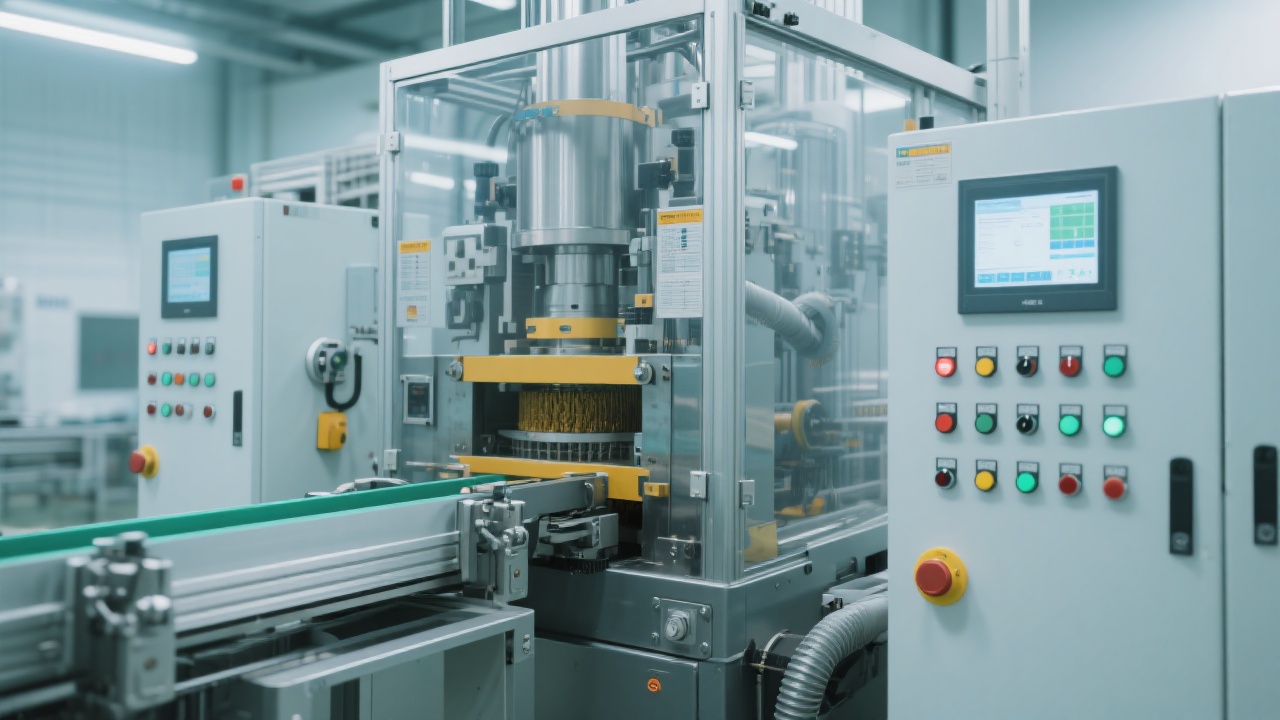

In today’s competitive edible oil industry, precision and efficiency are paramount. If you’re managing a fully automatic canola oil production line, mastering PLC (Programmable Logic Controller) control systems is your key to transforming operational complexity into streamlined productivity. Whether it’s raw material handling or filling and packaging, PLC offers comprehensive control, real-time anomaly detection, and remote monitoring capabilities that catapult your production line’s performance.

A well-configured PLC acts as the ‘brain’ of your edible oil production line. From managing the temperature during cold pressing to synchronizing motor speeds in the extraction and refining processes, PLCs ensure that each module operates within optimal parameters. This control precision reduces energy waste and enhances product consistency — imagine cutting your energy consumption by up to 15% compared to manual controls.

| Control Method | Energy Consumption Reduction | Product Consistency Improvement | Unplanned Downtime |

|---|---|---|---|

| Manual Control | Baseline | Variable | High (Up to 12%) |

| PLC Automated Control | 15% Reduction | +25% Stability | Reduced by 60% |

Such improvements directly enhance your OEE (Overall Equipment Effectiveness) — arguably your strongest KPI for production performance. PLC’s closed-loop temperature control in the cold pressing module precisely maintains conditions within ±1°C, preventing oil quality degradation and maximizing yield.

You’ve probably encountered sensor false alarms or motor synchronization issues that cause unexpected downtime. Here’s how an experienced edible oil manufacturer solved this challenge:

“After integrating PLC log analysis, we identified that a temperature sensor was intermittently malfunctioning due to electrical noise near the pressurized tanks. Implementing filter algorithms and redundant sensors, we cut false alarms by 90%. Additionally, motor phase detection modules within the PLC synchronized dual extraction motors, removing speed deviation issues and reducing unplanned stops by 40% in six months.” — Customer: SunHarvest Edible Oils

Proactive maintenance and smart alarm management will keep your PLC system at peak performance:

With fluctuating production demands and technological advancement, modular PLC architectures provide the scalability you need. By compartmentalizing control units, integration with additional modules like solvent extraction or sophisticated filtration becomes seamless — all without overhauling your existing system. This flexibility means you can adapt your plant’s capacity or upgrade process steps with minimal downtime.

Harness the full potential of your PLC by combining closed-loop temperature control with dynamic pressure interlocks. Fine-tune alarm thresholds based on historic operational data to minimize nuisance alerts. Train your team regularly on PLC troubleshooting and remote diagnostic tools to reduce mean time to repair (MTTR).

Remember, when you master these techniques, you turn your PLC into your production line's "brain trust": empowering you with actionable insights and enabling uninterrupted, efficient operations. It’s time to say goodbye to frequent downtime and let every minute on your line create value.