Are you an automation engineer or production supervisor in the B2B edible oil manufacturing industry? Do you often face challenges in maintaining stable temperature during the oil pressing process, which can affect oil yield and nutrient retention? If so, you're in the right place. This article will guide you through how to use PLC to achieve temperature closed-loop control in the pressing section of the edible oil production line, helping you solve practical operation and maintenance pain points.

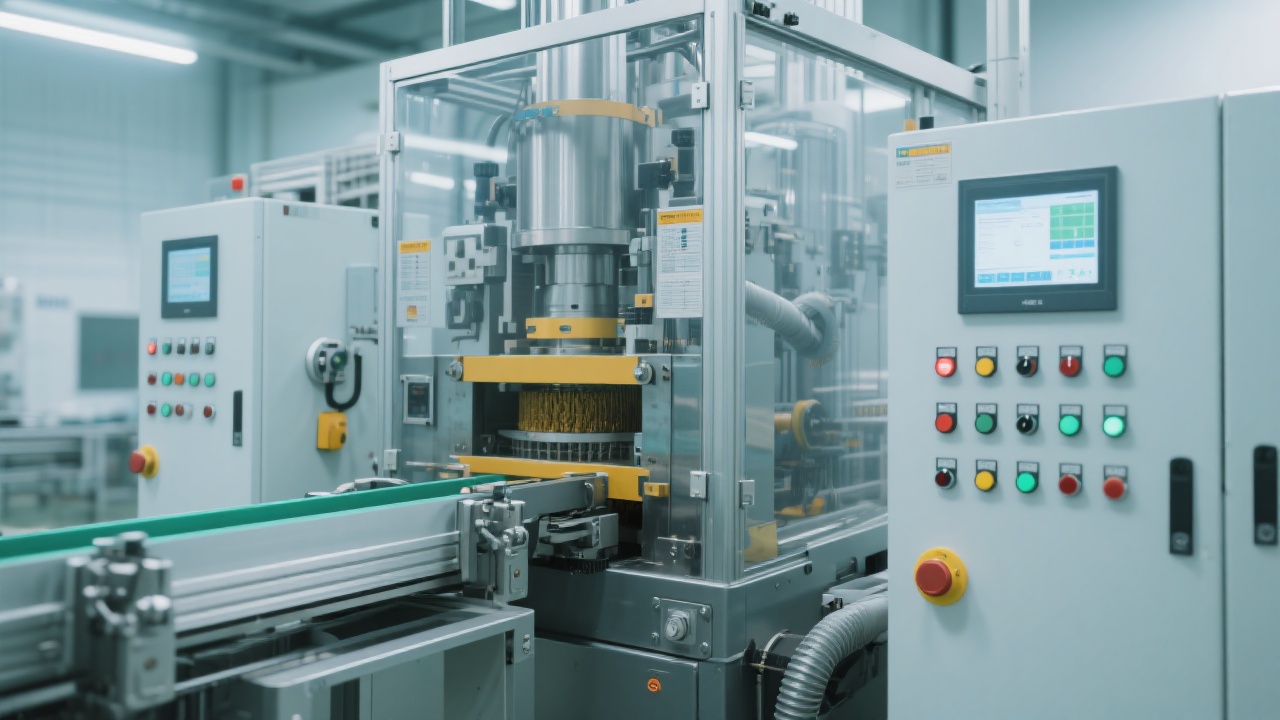

In the fully automated rapeseed oil production line, the PLC system plays a crucial role in the cold pressing stage. It works by integrating sensor feedback with the PID algorithm to adjust the heating unit. Sensors continuously monitor the temperature of the pressing process. Once the temperature deviates from the set range (e.g., 60 - 75°C), the PID algorithm calculates the appropriate adjustment and sends signals to the heating unit to ensure the temperature remains stable.

Here are some key aspects to understand:

Let's take a look at the differences between traditional manual control and PLC automatic adjustment in terms of energy consumption and consistency through data:

| Control Method | Energy Consumption | Temperature Consistency |

|---|---|---|

| Traditional Manual Control | High. Manual control often leads to over - or under - heating, resulting in about 15% more energy consumption compared to PLC control. | Poor. Manual operation is prone to human errors, causing significant temperature fluctuations, which may affect oil quality. |

| PLC Automatic Adjustment | Low. Precise control reduces unnecessary energy waste, achieving about 15% energy savings. | Good. The PLC system can maintain the temperature within a narrow range, ensuring consistent oil quality. |

Let's look at a real - world example. One of our clients experienced fluctuations in oil quality due to temperature control failure. Their traditional manual control method couldn't maintain a stable temperature, resulting in inconsistent oil yield and nutrient content.

"After implementing our PLC temperature closed - loop control system, we analyzed the PLC logs and found that the problem was caused by incorrect PID parameter settings. After adjusting the parameters, the temperature became stable, and the oil quality returned to normal. The production downtime was reduced by 30%, and the overall equipment efficiency (OEE) increased by 20%." - Client Testimonial

To help you better manage the temperature control process, we provide a list of practical tools:

The PLC system we offer features modular customization, which means it can be easily adapted to different production capacity requirements. Whether you have a small - scale or large - scale production line, our system can be customized to fit your needs. Its high compatibility and scalability ensure that it can integrate well with your existing equipment, providing long - term support for your production.

Let every degree of temperature create profit for you! Say goodbye to frequent downtime and start with precise temperature control. If you want to learn more about how our PLC temperature closed - loop control system can benefit your edible oil production line, click here to get in touch with our experts.