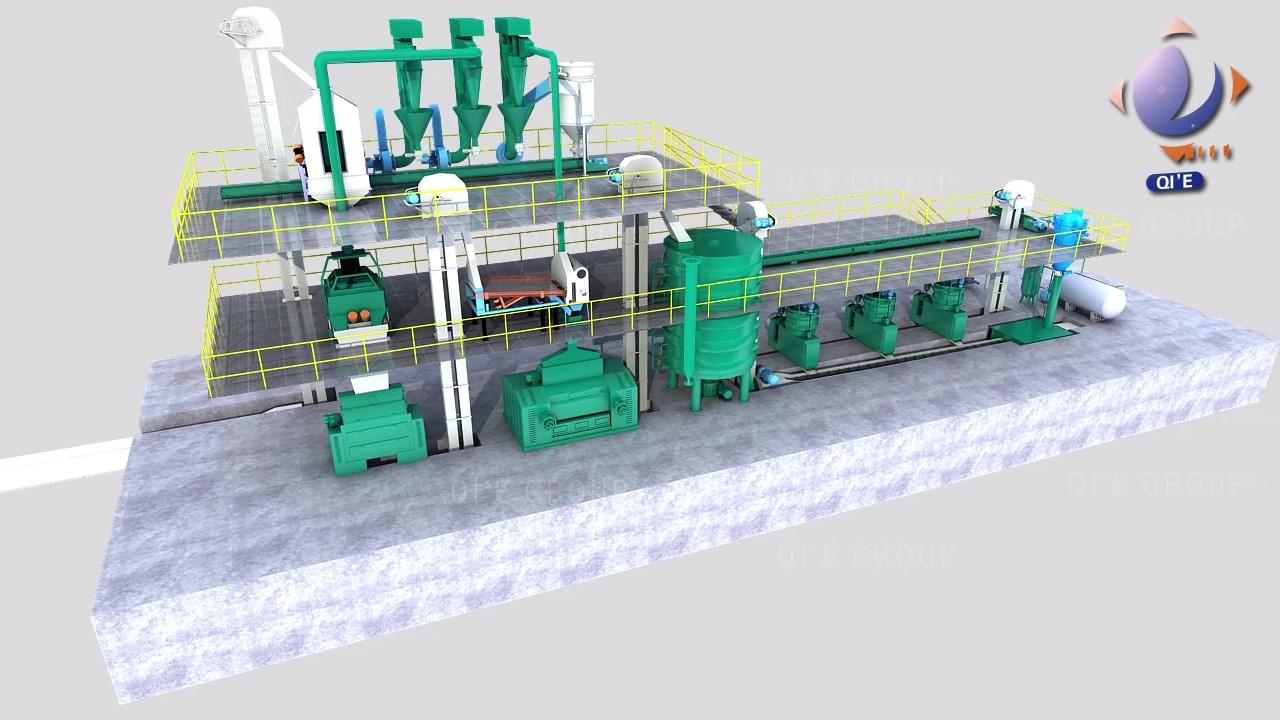

If you're managing a sesame oil production facility, you know that consistent quality and uptime are non-negotiable. That’s where a well-tuned automatic control system comes in—not just as a convenience, but as the backbone of your operational efficiency.

Modern sesame oil lines rely on programmable logic controllers (PLCs) to manage everything from temperature profiles to flow rates. A study by the International Association of Food Engineers found that plants using properly configured PLC systems saw up to 27% reduction in downtime and 18% improvement in yield consistency within six months.

| Component | Key Role |

|---|---|

| PLC Unit | Central processing for real-time adjustments |

| HMI Touchscreen | User-friendly interface for monitoring & manual override |

| Temperature Sensors | Feed data for PID loop optimization |

One common challenge? Inconsistent heat distribution during extraction. The solution lies in integrating temperature sensors with flow meters via a coordinated PID algorithm—this ensures precise thermal control across batches. For example, one client in India reported a 12% decrease in energy waste after tuning their PID parameters based on actual process variability rather than default settings.

“After implementing our custom control logic, our batch-to-batch variance dropped from ±5°C to under ±1.5°C. This made a huge difference in meeting export standards.”

— Rajesh Kumar, Plant Manager, Gujarat Oil Co.

Even the best system needs care. Here’s what we recommend checking monthly:

When issues arise—like sudden pressure spikes or inconsistent viscosity readings—it’s often due to misconfigured thresholds. Our troubleshooting flowchart helps engineers isolate root causes faster. One customer saved over 12 hours of downtime per incident after adopting this method.

You don’t need to reinvent the wheel. Whether you’re scaling from a small family mill to a regional hub, or upgrading an older line, there’s a tailored automation path for every stage.

Ready to take full control of your sesame oil production? Download the complete PDF guide now — including step-by-step setup instructions, sample code snippets, and a checklist for first-time commissioning.